It’s another quick tip from Kremin! Today we’re going to show you an amazing tool for keeping completed parts organized – the unassuming egg crate!

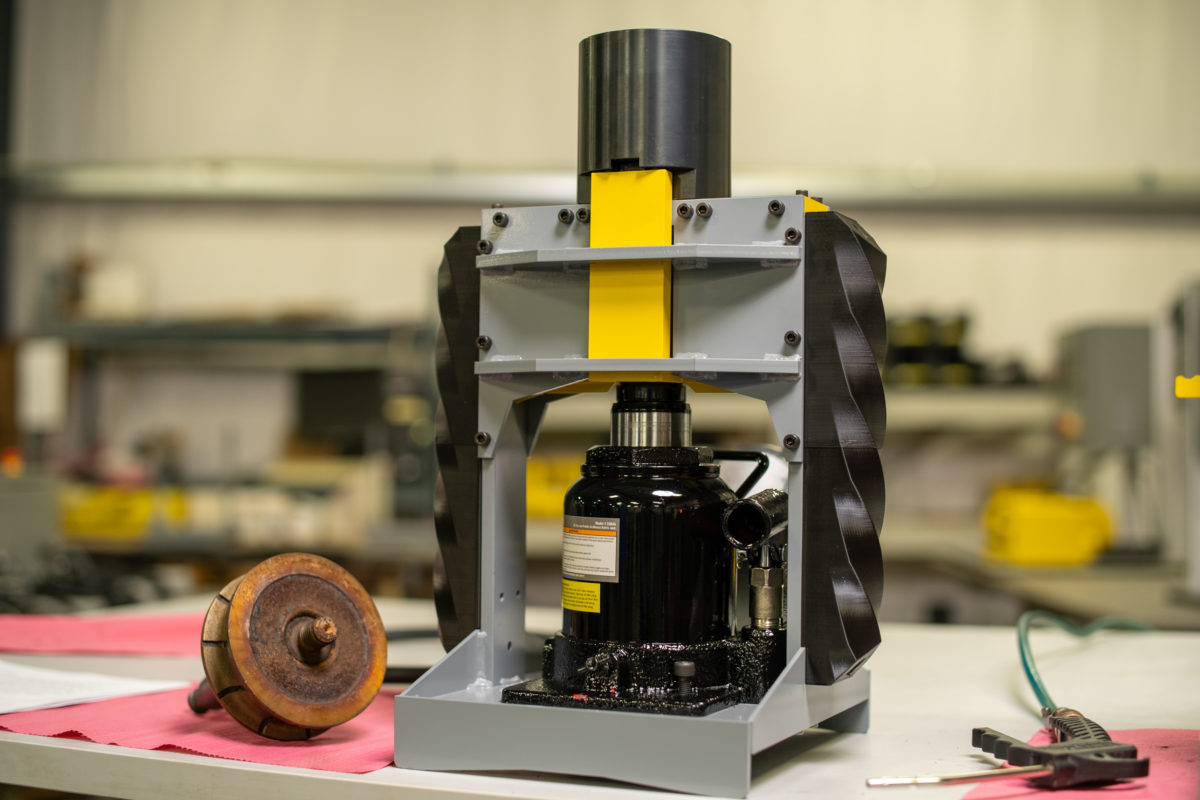

The AdVice Press Stand for Stone Shops

Does your diamond profiling tool keep getting caught in the cone? Spending too much resources on EDM? It can be tricky to get tooling unstuck, and it’s costly to just replace them. With our solution, the AdVice Press Stand, you can safely and easily remove tools from a cone, even if it’s worn down and stuck.

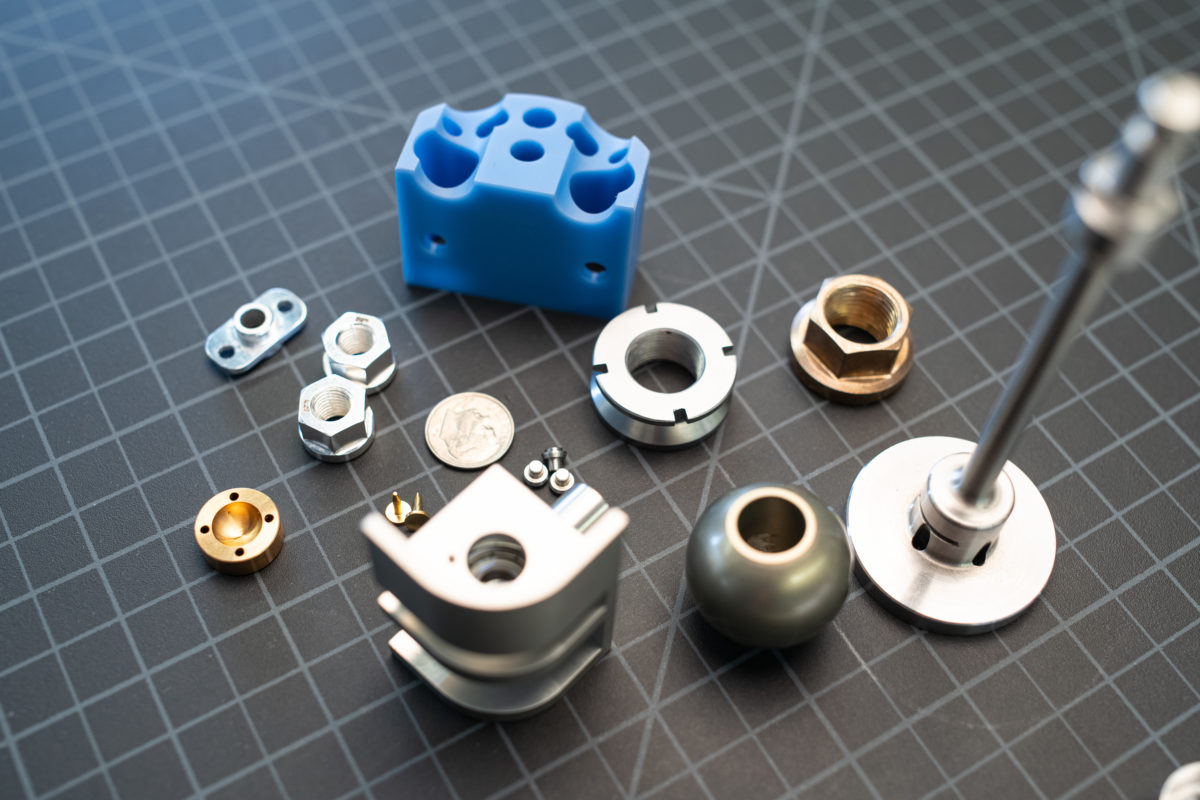

How to Properly Maintain Your Stone Cutting Tools

Dimensional stone manufacturing is very hard on the equipment and can damage tooling over time. Damaged tooling in turn can damage a machine, adding up in costs! You can prevent this. Take our tips on inspecting and maintaining your stone toolholders and pull-studs now!

The Advantedge: The Ultimate Tool Dressing Machine for Dimensional Stone Manufacturers

The Advantedge Dressing Machine – a system for easily dressing your stone cutting tooling off-line. Any stone shop with a CNC router MUST have this! The Advantedge Dressing Machine is only available from Kremin Inc.

What is Interpolation Milling?

One advanced production technique we use at Kremin is called interpolation milling. This allows us to achieve even more features on a single piece with one machine set-up, as opposed to many different set-ups that can cause variance issues.