CNCSwiss Screw Machining

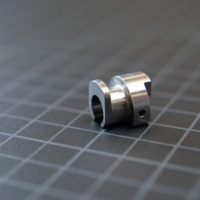

Whether it’s a component in a helicopter rotor or a pacemaker, sometimes the smallest parts matter the most in a machine that performs with lives on the line. These critical parts cannot be overlooked or manufactured improperly. When you need precision and detail in small, complex parts; you need Swiss Screw CNC Machining.

What is Swiss Screw CNC Machining?

Swiss Screw machining, or Swiss turning, is a type of specialized process for machining small parts that are performed on a Swiss Screw CNC Machine, or Swiss lathe. This machine pushes and spins material through a guide bushing where tools come into contact and cut it down with extreme precision. As parts get smaller, the advantages of Swiss turning become even greater since traditional lathes can exert too much pressure on small parts during the process and destroy them. In short, the Swiss Screw Machine is the best for turning small, complex parts.

Related Articles

When it comes to experience working with Citizen swiss lathes, Kremin Inc. really is the veteran. We have 5 different models of Citizen swiss lathes in our machine shop, so we’ve seen the good, the bad AND the ugly. How does the Cincom L32 stack up? Find out now.

Swiss Lathes At Kremin

CNC Turning/Machining Centers

| Qty. | Type | Controls | Capacity (X-Y-Z) |

|---|---|---|---|

| 2 | Citizens A20VII Swiss Lathe with 12’ auto Bar feeder 1) NEW in 2011 1) NEW in 2014 | FANUC | 20mm Diameter |

| 3 | Citizens A32VII Swiss Lathe with 12’ auto Bar feeder 1) NEW in 2012 1) NEW in 2015 | Mitsubishi | 32mm Diameter |

| 3 | Citizens L32XII Swiss Lathe with 12’ auto Bar feeder 1) NEW in 2017 1) NEW in 2019 1) NEW in 2020 | Mitsubishi | 32mm Diameter |

| 1 | Citizens L20E Swiss Lathe with 12’ auto Bar feeder NEW in 2014 | Mitsubishi | 20mm Diameter |

| 1 | Citizens K16EVII Swiss Lathe with 12’ auto Bar feeder NEW in 2021 | Mitsubishi | 16mm Diameter |