Precision Manufacturing ForIndustrial Projects

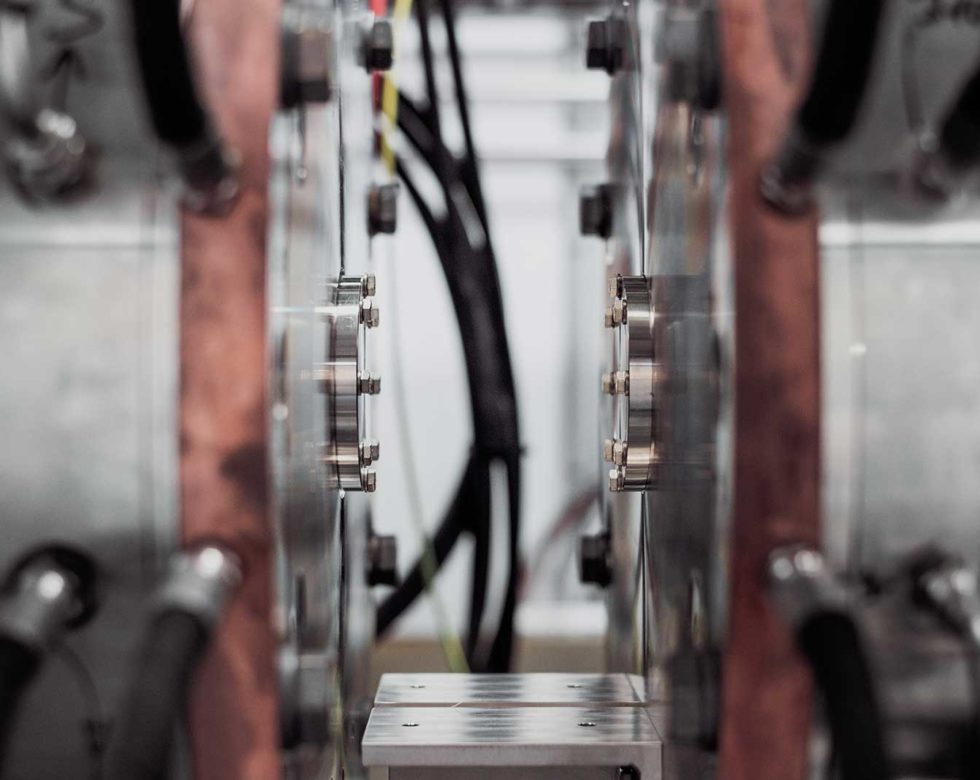

Kremin brings value to industrial and transportation partners by providing them with the full spectrum of contract manufacturing services that allow them to get more done under one roof. It’s simple: fewer set-ups = quicker deliveries and less overhead. We have outfitted ourselves to take mid-volume productions all the way from custom machining to finishing to even shipping and packing.

We can provide industrial and transportation companies with a “one and done” shop that allows them to manage less vendors. Original Equipment Manufacturers (OEMs) around the world rely on us to simplify their process while still maintaining the highest quality in parts.

Thanks to our state-of-the-art quality control system, our shop has been certified to ISO 9001:2015 and ISO 13485:2016 standards. Our smaller size gives us great agility when it comes to getting started on new projects or responding to our partners’ needs.

Sound like we can help you? Talk to our engineers about your industrial or automotive project now!

OurCapabilities

Kremin can provide full contract manufacturing services beyond just machining and turning.

We can also handle:

- Swiss Screw Machining

- CNC Turning

- CNC Milling

- Grinding Services

- Finishing Services

- Quality & Inspection Services

- Labeling

- Bar Coding

- Packaging

- Pull System for Lean Manufacturing Strategies

- KANBAN Scheduling Systems

See our shop’s equipment now.

Materials & Sizes Supported

We frequently work with common and exotic materials like stainless steel, inconel, copper, brass, titanium, and multiple grades of aluminum.

- Our swiss lathes can machine down to 1/16” and up to 1¼” material.

- Our mills can mill materials up to 30” × 16” × 20” and 25″ x 59″ x 25 (X-Y-Z)

- Conventional turning operations from 1/8” to 18” in diameter.

- Chucker lathes can machine from 1/16” to 3” in diameter through the spindle, chuck up to 18″ diameter with 30” swing.